about REES lift

REES Industries

Safer Indoor AWP Expert-REES Industries is a Chinese manufacturer of CE certified aerial working platforms. Our company is located in Feicheng Bianyuan Economic Area, Shandong, China, engaged in Vertical lifts and Scissor Lifts design, production and sales. From the very beginning, we have been dedicated to providing customers with safer indoor aerial working platforms.

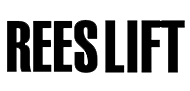

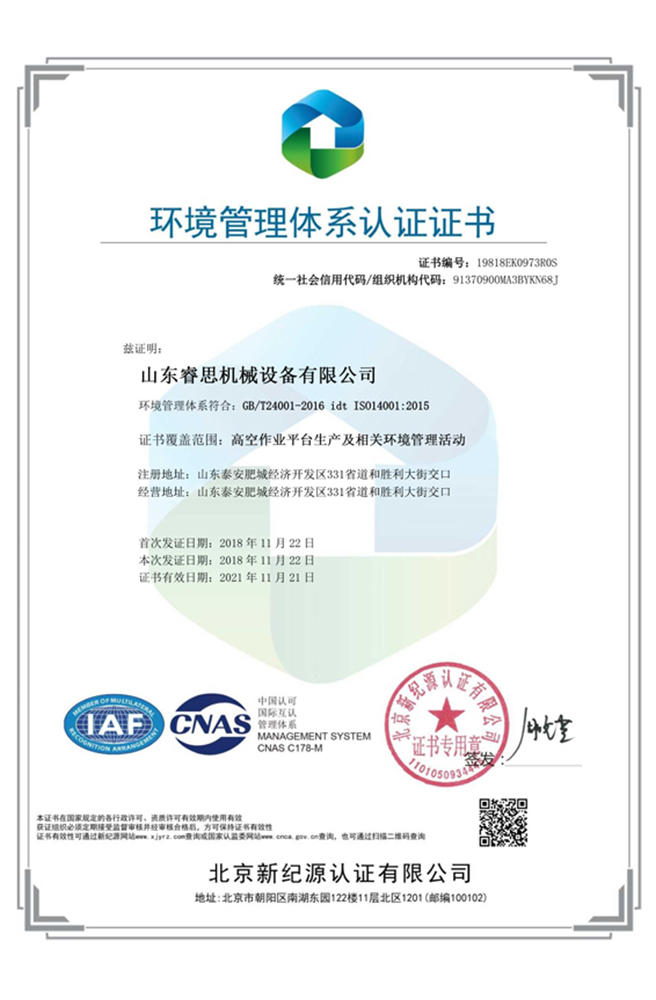

As a professional China Double Mast Vertical Lifts manufacturers and Double Mast Vertical Lifts factory, relying on years of production experience, REES continuously adopts new technologies, new processes and new materials, implements ISO 9001, ISO 14001 and ISO 18001 standards of international quality management system, international environmental management system, and international health and safety management system, and all its products have passed CE certification in Europe. The technical indicators have reached a high level in the same industry in China, and occupied the market with reasonable prices and good services. They are deeply trusted by the vast number of users. The products are exported to more than 100 countries and regions in Europe, Asia and the United States.

-

0

Enterprise establishment

-

0+

Product Varieties

-

0+

Product category

-

0

Production capacity

Español

Español