REESLIFT, a company focus on indoor aerial work platforms, is proud to announce a comprehensive upgrade to push-around aluminum aerial work platforms, delivering an enhanced user experience.

Key highlights of this upgrade include:

1.Curvature end on outriggers: The end of the outrigger is treated with a curvature, and there is no need to remove the positioning pin during installation of it.

2.The foot cup adopts a Genie-structured die-cast aluminum with a plastic wrapping, which is aesthetically pleasing, doesn’t cause damage to the ground, and prevents detachment.

3.Spherical Handle Design: The control handle has been upgraded to a spherical design, providing a more ergonomic and user-friendly operation for seamless control.

4.TPU Caster Wheels: With TPU material caster wheels—lightweight, wear-resistant, highly elastic, and corrosion-resistant, ensuring reliable performance in diverse environments.

5. Braking device on swivel casters: Add braking devices on swivel casters to improve the stability of the equipment when poisoning at workplaces.

6. The loading crossbar has been thickened and treated with galvanization, providing higher strength for increased safety during loading.

7.Oil Drip Tray Mechanism: The platform now features an oil drip tray mechanism, effectively preventing oil leaks and reducing ground risks, particularly beneficial for indoor aerial work.

8. Replacing the visible bubble level with an electronic-style horizontal sensor for a more sophisticated and secure design.

9. Chassis material changed: Changing the chassis material from Q235 to Q345 for increased strength, resulting in reduced equipment vibration.

10. Electrophoretic coating for vehicle structural components: Enhanced corrosion resistance and increased lifespan.

11. The height of easy loading is increased from 800mm to 950mm.

12. Four Bracing Bar Design: Upgrading from the previous two bracing bars to four enhances equipment stability, providing greater safety assurance for aerial operations.

13. Green denotes the single-person loading cushion: Effective shock absorption and protection of the body structure when loading and unloading.

14. The loading wheels have been upgraded to aluminum core material for increased strength.

15. The connection between the platform frame and the body has been improved from two fixed clips to four, resulting in a more secure and robust connection.

16. The platform frame material has been upgraded from 5052 to 5083, providing higher strength and lighter weight.

17. Implemented a platform cushion structure: When entering the platform frame, it prevents the platform frame from dropping due to weight, enhancing the user experience.

18. The emergency lowering device is now located at the bottom of the hydraulic cylinder, providing a more scientific arrangement.

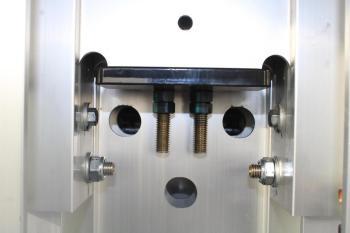

19. Fully submerged hydraulic cylinder: During oil return, oil is present in the oil chamber simultaneously, preventing internal corrosion and oil contamination. The cylinder valve is integrally welded, avoiding poor sealing and oil leakage issues.

20. Chain observation hole: Allows observation of chain conditions anytime.

21. Sliding blocks: Adjustable clearance ensures the stability of the equipment during use.

22. Self-leveling chain: Two chains self-level to ensure even force distribution and prevent a situation where a single chain bears all the force.

23. Loading hook: When using the easy- loading function, the loading hook connects the chassis and aluminum structure together, protecting the internal structure of the profile.

24. Equipped a dual-hook safety belt, meeting the safety requirements of a five-point double-hook safety belt.

25. Synchronized steel wire rope (optional) ensures simultaneous raising and lowering between masts.

26. Emergency lowering on platform control: Emergency lowering on platform control to ensures the workers working on aluminum working platforms meets the emergency situations such as powered off or plug off, to ensure safety.

REES’s commitment to improving product performance and safety, coupled with a dedication to meeting the diverse needs of customers, is evident in this upgrade.

For more information, you can leave a message, and we will contact you as soon as possible.

Español

Español